Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

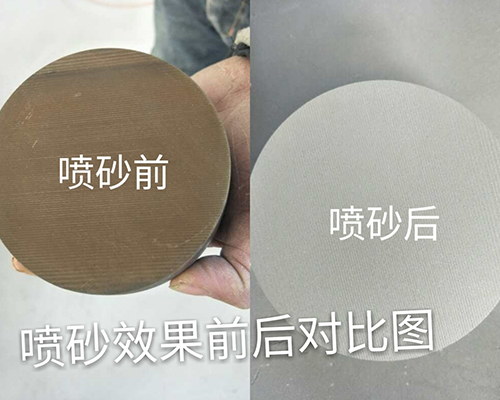

Dalian sanding and derusting is divided into dry sand blasting and water sand blasting, which mainly uses particle jet erosion to achieve surface cleaning. This method is suitable for removing a large amount of rust and impurities on the surface of the paint, which is of high quality and is suitable for removing rust and impurities on the surface of the paint. Remove the oil stain, paint stain, rust scale, etc. on the surface. For Grade 1 reinforcement, in order to remove the rust scale while cold drawing and straightening, the cold drawing rate can be appropriately increased within the allowable range of the specification. At present, mechanical derusting machine is commonly used for derusting, with high derusting efficiency, stability and simple operation. The derusted reinforcement has no scratches, and there are environmental protection devices that do not pollute the environment.

Sand blasting process: it uses compressed gas to eject spraying materials (commonly used spraying materials include copper ore, quartz sand, emery, iron sand, Hainan sand, etc.) to the surface of the workpiece by means of high-speed air pressure. Under the impact and cutting of the spraying materials on the surface of the workpiece, the surface can obtain a certain degree of cleanliness (such as rust removal).

Sand blasting derusting uses compressed air as the power to form a high-speed jet beam to spray the spraying materials (copper ore, quartz sand, emery, iron sand and Hainan sand) to the workpiece surface to be treated at high speed. Due to the impact and cutting effect of abrasive on the workpiece surface, the sundries on the workpiece surface are removed, so that the workpiece surface can obtain certain cleanliness and different roughness, increase the adhesion with the coating and prolong the durability of the coating, It is also conducive to the leveling and decoration of the coating. In addition, the appearance or shape of the workpiece surface is changed, and the mechanical properties of the workpiece surface are improved, so the fatigue resistance of the workpiece is improved.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |