Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

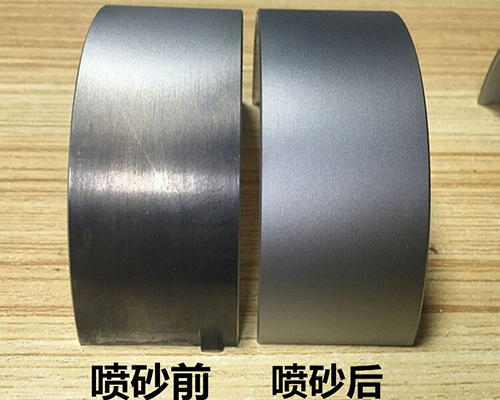

Dalian sand blasting and shot blasting processing, sand blasting stainless steel is also a popular product in the color stainless steel plate industry. After electroplating process, it has become the second largest process in the industry. After using sand blasting technology on the smooth surface of stainless steel, it can improve the fineness of the surface. Secondly, it increases the uniformity of the whole decorative panel. While improving performance, it will not forget to take value to new heights.

To use an analogy, stainless steel is short and poor, and sandblasted stainless steel is really rich and handsome. The sand blasting machine on the market is simply divided into manual and automatic Because to be suitable for different types of products, various configurations suitable for their own products will be added For example, the machine becomes a wet sandblasting machine by adding water, the machine becomes a pressurized sandblasting machine by adding a pressurized tank, and the machine becomes a high-end sandblasting machine by adding a touch screen Manual and automatic, the former is manual control sandblasting, and the latter is automatic sandblasting. Dry ice spray can be used for various materials, such as steel, as well as softer materials, such as aluminum.

The results of shot peening process vary from material to material, so dry ice spraying is a custom designed process. In general, it can be said that the increase of residual stress, hardness and surface roughness is achievable, but there is a correlation between these effects. Increasing surface roughness usually means that the surface hardness value decreases at the same time. One disadvantage of the dry ice spraying process is the requirements for the working environment: in this process, a sound pressure level of up to 125dB (a) may occur and the concentration of CO 2 in the surrounding air may be increased.

In addition, the investment cost of process automation is usually high. Because sand was the only abrasive that could be used in the initial stage of the emergence of shot peening technology, shot peening has been called sand blasting at that time and for a long time later. Sand blasting can make the cleaned surface obtain the required cleanliness and a certain roughness at the same time, and improve the adhesion of the coating on the basic surface. No matter how good the coating is, it can not be well attached to the workpiece surface without surface treatment for a long time.

As a conventional abrasive jet technology, after continuous development, improvement and improvement, with its unique processing mechanism and wide range of processing and application, it is more and more popular in today's surface treatment industry. It has been widely used in machinery manufacturing, instruments, medical devices, electronic appliances, textile machinery, printing and dyeing machinery, chemical machinery, food machinery, tools, cutting tools, measuring tools, molds, glass, ceramics Crafts, mechanical repair and many other fields.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |