Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

Corrosion of metal materials is an eternal and destructive problem in fields such as industrial manufacturing, ship maintenance, bridge construction, and heavy equipment maintenance. Corrosion not only affects the appearance of products, but also seriously weakens the strength, durability, and safety of materials. Therefore, rust removal is a crucial and indispensable first step in many manufacturing processes. Among numerous rust removal methods, Dalian shot blasting stands out with its excellent efficiency, outstanding results, and profound economic benefits, and is known as the essential "ace" technology for rust removal. This is not an exaggeration, but rather determined by its unique working principle and the comprehensive advantages it brings.

1、 Beyond 'Rust Removal': Working Principle and Core Advantages of Shot Blasting Processing

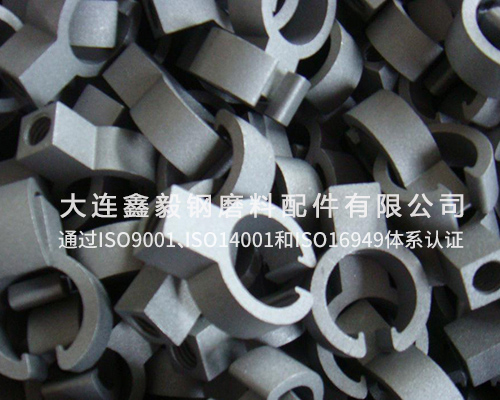

The core of shot blasting is to use mechanical equipment (shot blasting) to project a large number of high-speed pellets (usually steel pellets, steel wire cutting sections, stainless steel pellets, angular steel grit, etc.) onto the surface of the workpiece by centripetal force. Through high-speed impact and friction, the rust layer, oxide scale, old paint, oil stains, and other impurities on the surface are peeled off.

Compared with traditional methods such as manual polishing, chemical pickling, and high-pressure water jet, the advantages of shot blasting are comprehensive and revolutionary:

High cleaning efficiency and consistency: Manual polishing has low efficiency and heavily relies on worker skills, making it difficult to achieve uniform quality. The chemical pickling process is slow and has environmental and waste liquid treatment issues. The shot blasting machine, through mechanical automation, can continuously and rapidly process a large number of workpieces, whether it is huge steel plates, complex castings, or a large number of small parts. It can achieve international standard cleaning levels of Sa2.5 (very thorough cleaning level) or Sa3 (making the metal reveal a uniform metallic color) in a short period of time, which is difficult for manual labor to achieve.

Simultaneously achieving "surface activation" and "strengthening": this is the value of the essence of shot blasting technology, far beyond simple "rust removal".

Stress relief: The impact of high-speed projectiles can effectively eliminate tensile stress on the surface of the workpiece, and even generate beneficial compressive stress layers.

Surface strengthening (shot peening): This compressive stress layer can greatly improve the fatigue strength of metal parts, delay the generation and propagation of cracks, and significantly extend the service life of the workpiece. This function is crucial for key components that can withstand alternating loads, such as engine crankshafts, gears, springs, etc.

Increasing adhesion: The impact of the projectile will form numerous uniform and fine pits (i.e. anchor lines) on the metal surface, significantly increasing the surface area. This provides an excellent adhesion foundation for subsequent spraying and coating, making the coating less prone to peeling and doubling the anti-corrosion effect.

Environmental protection and cost-effectiveness: Modern shot blasting equipment is usually a closed loop system. The pellets used can be reused after recycling, sorting, and dust removal, with low material consumption. Compared to chemical acid washing, it does not discharge harmful chemicals, avoiding serious environmental pollution and complex wastewater treatment costs. Although the initial investment in equipment is relatively high, from the perspective of long-term large-scale production, it has high per capita efficiency, controllable consumable costs, and outstanding comprehensive cost-effectiveness.

Automation and Integration: Shot blasting equipment is easy to integrate into automated production lines, achieving full automation from loading, shot blasting cleaning, dust removal, to unloading, in line with the development trend of modern intelligent manufacturing, greatly reducing dependence on manpower and uncontrollable factors.

2、 An indispensable application scenario

The necessity of shot blasting is fully demonstrated in the following key areas:

Ship and Ocean Engineering: Giant ship structures such as steel plates, decks, and ballast tanks are exposed to harsh environments with high salt and humidity for a long time, requiring high requirements for rust removal and painting. Shot blasting is the only process that can efficiently and thoroughly process large surface areas and form high standard anchor pattern contours.

Bridges and steel structures: The anti-corrosion requirements for long-term outdoor exposure of steel structure bridges, building frames, transmission towers, etc. are crucial. Shot blasting not only thoroughly removes rust, but its surface strengthening effect can also extend the safe life of structures under dynamic loads such as wind and vehicle loads.

Automotive manufacturing industry: The frame, chassis, wheels, and other components of a car must undergo shot blasting treatment before spraying to ensure the reliability of decades old anti rust coatings. Many key components inside the engine rely on shot blasting to improve their fatigue life.

Casting industry: Cleaning sand particles, oxide scales, and burrs on the surface of castings is a traditional strength of shot blasting machines, which can return a clean and smooth metal surface to castings.

Wind power and aerospace: These high-end fields have strict requirements for material reliability and lifespan, and shot blasting strengthening is almost a standard and essential process for high stress components.

The ultimate definition of essential craftsmanship

In summary, the reason why shot blasting has become an "essential" process for rust removal is not only because it can "remove rust", but also because it efficiently completes basic cleaning tasks while giving metal workpieces a second life - a new surface that is stronger, more durable, and easier to protect.

It transforms a passive and defensive "rust removal" step into an active and value-added "strengthening" process. This dual value of solving current problems (rust removal) and investing in future performance (strengthening and increasing adhesion) has made shot blasting beyond the scope of ordinary processes and an indispensable foundational link in modern industrial systems. It is not an optional choice, but an inevitable choice for pursuing quality, efficiency, environmental protection, and long-term economic benefits, rightfully standing at the top of the king of surface treatment technology.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |