Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

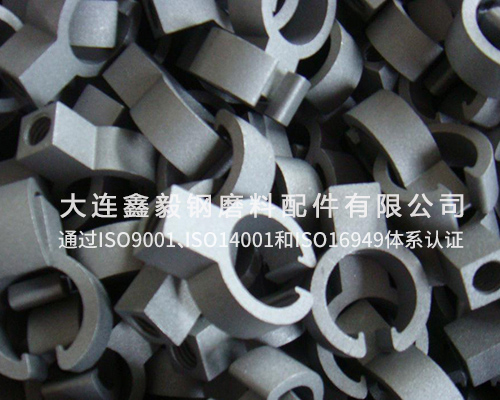

Dalian shot blasting is an effective metal surface treatment process that can achieve cleaning of metal surfaces, increase roughness, and improve strength. In modern industrial production, shot blasting has become an indispensable metal processing technology, providing important support for improving the quality and performance of metal products.

Through shot blasting processing, a strong and uniform surface layer is formed on the metal surface, which has a certain degree of hardness and wear resistance, effectively extending the service life of the metal material and improving the wear resistance of the product. Shot blasting equipment is easy to operate, and the surface treatment effect of the product can be controlled by adjusting the processing parameters during the processing. Suitable processing techniques and abrasives can be selected according to different processing requirements to meet the processing needs of different products.

How to avoid producing waste in Dalian shot blasting processing?

Proper maintenance and upkeep of processing equipment is necessary. Shot blasting equipment is the core equipment of shot blasting processing. Only by ensuring the normal operation of the equipment can the processing effect and product quality be guaranteed. Therefore, it is necessary to regularly inspect all components of the equipment, promptly repair any problems found, and ensure the normal operation of the equipment.

Secondly, it is necessary to choose suitable shot blasting particles and processing parameters. Different metal materials and processing requirements require the selection of different shot blasting particles and processing parameters. Only by selecting appropriate particles and parameters can the processing effect and product quality be ensured. Otherwise, it may lead to unsatisfactory processing results and produce waste products.

In addition, it is necessary to strengthen the control and management of the process flow. Shot blasting is a complex process that requires precise control and management of every step. Regularly inspect and adjust the process flow, promptly identify and solve problems, and ensure product quality.

At the same time, it is necessary to strengthen the training and management of operators. The technical level and quality of operators directly affect the effectiveness and quality of shot blasting processing. We need to strengthen the training and development of operators, ensure that they master the correct operating methods and technical requirements, improve their operational skills and sense of responsibility, and avoid the production of waste products due to improper operation.

To establish a sound quality management system. Quality management is the foundation of enterprise development. Only by establishing a sound quality management system can we ensure product quality and production efficiency. We need to strengthen the monitoring and testing of the production process, establish a quality tracking system, timely identify and solve problems, and avoid the production of waste due to quality issues.

Shot blasting is a common surface treatment process mainly used to remove impurities such as oxide scale, welding slag, rust, oil stains, etc. on metal surfaces, in order to improve the smoothness and roughness of metal surfaces, enhance the adhesion and wear resistance of metal materials. Shot blasting usually uses metal pellets or abrasives to accelerate in a high-speed rotating working wheel, utilizing high-speed impact and cutting effects to strip or remove impurities from the metal surface, thereby achieving surface cleaning and modification effects.

Shot blasting can be divided into two methods: dry shot blasting and wet shot blasting. Dry shot blasting refers to the process of shot blasting without a liquid medium, mainly suitable for metal surface cleaning and removal of oxide layers. Wet shot blasting refers to the process of shot blasting in water or other liquid media, mainly used for rust removal, oil removal, slag removal and other processes on metal surfaces. Both shot blasting methods have their own advantages, so choose the appropriate shot blasting method according to different processing requirements.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |