Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

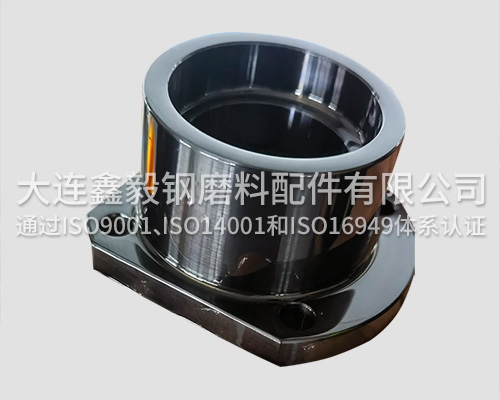

Dalian blackening surface treatment is a chemical reaction that forms a dense oxide film on the metal surface. This oxide film can effectively prevent oxygen, moisture, and other corrosive media from contacting the metal substrate, thereby improving the corrosion resistance of the metal. At the same time, the oxide film can also increase the hardness and wear resistance of the metal surface, improving the service life of the metal.

The blackened metal surface presents a uniform black or blue black color, which has a certain decorative value. This color not only complements other components better, but also adds a stable and professional appearance to the product. For example, the metal shells of some mechanical tools and instruments appear more delicate after blackening treatment.

How much can the surface hardness of metal parts be improved after blackening surface treatment in Dalian?

Blackening treatment mainly forms a dense oxide film, which has relatively limited improvement on the surface hardness of metal parts.

Generally speaking, after blackening treatment, the surface hardness of metal parts may increase by about 5% -15%. The specific degree of improvement depends on various factors, such as the type of metal material, original hardness, and the process parameters of blackening treatment.

For example, for some medium and low carbon steel materials, the original hardness is relatively low, and the surface hardness may increase by 10% -15% after blackening treatment; For high hardness alloy steel and other materials, blackening treatment may only increase surface hardness by 5% -10%.

It should be noted that the main purpose of blackening treatment is to improve the corrosion resistance, wear resistance, and appearance quality of the metal, rather than significantly increasing the surface hardness. If it is necessary to significantly improve the surface hardness of metal parts, heat treatment processes such as quenching, carburizing, nitriding, or surface coating techniques can be considered.

In the electronic and electrical industry, blackening treatment is mainly used to improve the corrosion resistance and conductivity of metal parts, ensuring the performance and reliability of electronic and electrical products. For example, in industries such as electronic component manufacturing, wire and cable manufacturing, and electrical equipment manufacturing, blackening treatment is widely used for surface treatment of various metal parts.

Many metal parts in automotive components, such as engine components, chassis components, brake system components, etc., require surface treatment to improve their performance and durability. Blackening treatment is a commonly used method that can provide excellent corrosion resistance and wear resistance for automotive parts, while also meeting the requirements of the automotive industry for appearance quality.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |