Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

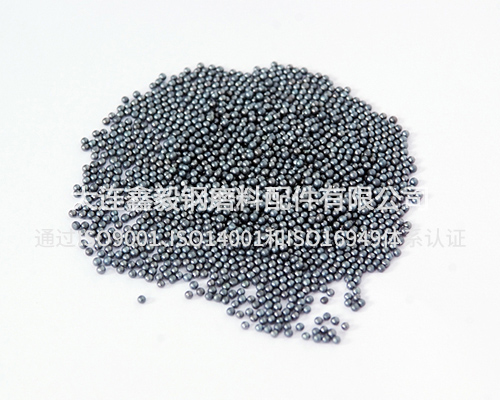

The characteristics of sandblasting processing in Dalian are its flexibility, customizability, and high quality. By adjusting sandblasting equipment, selecting abrasive types, etc., workpieces of different materials, shapes, and surface qualities can be produced. In addition, sandblasting service providers usually develop personalized processing plans based on customer requirements, which are particularly attractive to customers with personalized needs.

Sandblasting processing has been widely used in many fields. Mechanical manufacturing: used to clean the oxide scale and burrs on the surface of castings and forgings, improve the quality and service life of parts. For example, the cylinder block of a car engine is sandblasted before processing to remove residual impurities during the casting process. Metal anti-corrosion: Sandblasting pre-treatment is carried out on the metal surface to enhance the adhesion of the anti-corrosion coating and improve the anti-corrosion performance. Sandblasting is carried out on large steel structure bridges before painting to ensure the firm adhesion of the coating.

What materials are suitable for sandblasting in Dalian?

Here are some materials suitable for sandblasting:

Metallic materials:

Steel: including carbon steel, alloy steel, etc., commonly used for surface treatment of mechanical parts, steel structures, etc.

Aluminum and aluminum alloys: widely used for surface treatment of components in aerospace, automotive manufacturing, and other fields.

Copper and copper alloys: used for electronic components, decorative parts, etc.

Glass: Sandblasting can create a frosted effect, pattern or pattern on the surface of glass, commonly used for decorating glass, glassware, etc.

Stone: such as marble, granite, etc., sandblasting treatment can change the texture and appearance of the stone surface, used for architectural decoration.

Plastic: Some plastics with higher hardness, such as polycarbonate (PC), acrylic (PMMA), etc., can be sandblasted to obtain special surface effects or improve coating adhesion.

Ceramics: Sandblasting on the surface of ceramic products can increase their roughness or achieve specific decorative effects.

Wood: mainly used for wooden furniture or crafts that require special textures and appearance effects.

For example, in the automotive manufacturing industry, aluminum alloy wheels are often sandblasted to enhance their coating adhesion and appearance quality; In the field of architectural decoration, marble slabs can exhibit unique texture and style after sandblasting treatment.

The process flow of sandblasting mainly includes workpiece treatment, material selection, equipment selection, abrasive selection, sandblasting processing, cleaning, drying and other links before sandblasting. Compared with traditional manual operations, sandblasting has the advantages of high efficiency, precision, and high degree of automation, making it highly favored by the manufacturing and processing service industries.

Sandblasting processing has the following characteristics and advantages. Surface cleaning: It can effectively remove impurities such as oxide scale, rust, oil stains, coatings, etc. on the surface of the workpiece, making the surface clean. Increase roughness: Improve the surface roughness of the workpiece, enhance the adhesion of coatings, adhesives, etc. to the workpiece surface. Removing residual stress: improving the mechanical properties of the workpiece and reducing the occurrence of fatigue cracks. Shaping appearance: can create a uniform matte or frosted appearance effect.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |