Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

Dalian sandblasting is a commonly used surface treatment process that can provide cleaning, repairing, and improving surface quality effects. It is widely used in aviation, automotive, machinery, construction and other fields, and has the characteristics of simplicity, efficiency, and economy. When using sandblasting, attention should be paid to safety, environmental protection, and energy conservation to ensure good processing results and sustainable development.

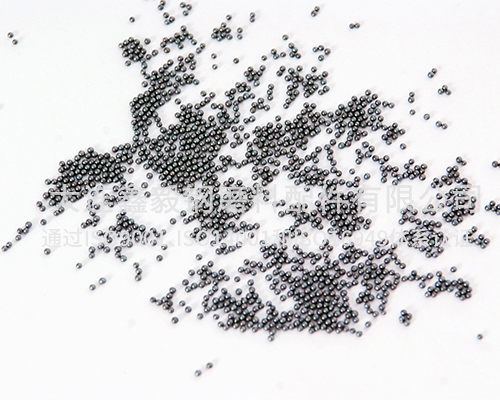

The selection of sand particles is a very important step in the sandblasting process. The size, hardness, and shape of sand particles can all affect the processing effect. Generally speaking, the larger and harder the sand particles, the faster and more obvious the processing effect. However, for materials with lower hardness, choosing too hard sand particles may lead to excessive surface scraping and damage to the material itself. Therefore, when selecting sand particles, it is necessary to determine based on the hardness and purpose of the material.

Can Dalian sandblasting achieve different texture and gloss effects?

Sandblasting can achieve different texture effects by adjusting the sandblasting pressure and the size of sandblasting particles. When the sandblasting pressure is high and the sandblasting particles are coarse, the sandblasting effect will be rougher, and the surface will present irregular granular texture, giving people a rough and wild visual effect. When the sandblasting pressure is low and the sandblasting particles are fine, the sandblasting effect will be more delicate, and the surface will present a uniform and smooth texture, giving people a delicate and elegant visual effect.

Secondly, sandblasting can also achieve different texture effects by adjusting the sandblasting angle. The different angles of sandblasting can cause changes in the direction of sandblasting particles, resulting in different texture effects. For example, when the sandblasting angle is large, sandblasting particles will spray towards the surface of the object at a larger angle, forming a clear horizontal texture effect; When the sandblasting angle is small, sandblasting particles will spray towards the surface of the object at a smaller angle, forming a fine longitudinal texture effect. By adjusting the sandblasting angle, different texture effects can be achieved, thereby achieving different visual effects.

In addition, sandblasting can also achieve different gloss effects by selecting different sandblasting particle sizes. The difference in sandblasting particle size directly affects the surface roughness of the object. When the sandblasting particles are coarse, it will cause a larger surface roughness, resulting in multiple reflections and scattering of light on the surface of the object, presenting a rough and matte effect visually. When the sandblasting particles are finer, it will result in smaller surface roughness, less reflection and scattering of light on the surface of the object, resulting in a smoother and more glossy effect on the object. By selecting different sandblasting particle sizes, different gloss effects can be achieved, resulting in objects presenting different textures.

The equipment for sandblasting mainly includes sandblasting machines, compressed air sources, abrasive supply systems, etc. The sandblasting machine shoots abrasive particles towards the material to be processed through a nozzle, and the compressed air source provides high compressed air. The abrasive supply system is responsible for transporting the abrasive particles to the nozzle. When sandblasting, operators need to wear protective equipment to prevent harm from abrasive particles to the human body.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |