Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

Key application of sand blasting antirust treatment for steel frame structure: Dalian sanding and derusting

(1) Solve problems before workpiece plating and workpiece bonding

Sand blasting can eliminate all wastes such as rust on the surface of the workpiece, create a very key basic diagram (generally speaking, the rough surface) on the surface of the workpiece, and achieve different levels of surface roughness according to the replacement of wear-resistant materials with different particle size distribution, so as to further improve the combination of the workpiece with architectural coatings and plating materials. Or make the bonding parts more firm and of stronger quality.

(2) Removal, grinding and polishing of rough surface and workpiece after heat treatment process of precision castings

Sand blasting can remove all wastes (such as oxide skin, oil stain and other residues) on the surface of precision castings and workpieces after heat treatment, polish and polish the surface of workpieces, improve the smoothness of workpieces, and beautify workpieces.

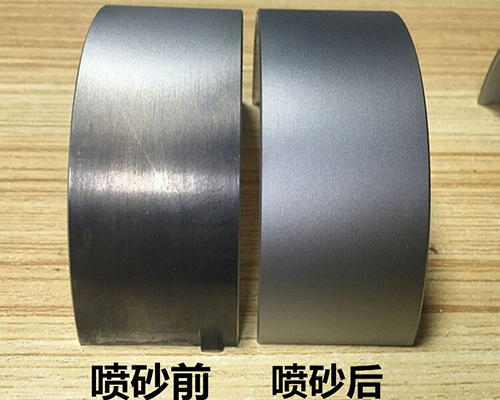

Sand blasting can make the workpiece expose the uniform primary color of metal materials, make the workpiece surface more beautiful and generous, and achieve the effect of beautifying the decorative design.

(3) Burr removal and surface beautification of machined parts

Sand blasting can remove the fine burrs on the workpiece surface, make the workpiece surface more flat, remove the damage of burrs and improve the level of the workpiece. Moreover, sand blasting can make a small arc at the intersection of the workpiece surface, which makes the workpiece look more beautiful, generous and fine

(4) Improve physical properties of parts

After sandblasting, mechanical parts can create symmetrical and small convex and concave surfaces on the surface of parts (basic figure), so that the grease can be stored, so as to improve the lubrication standard, reduce noise and improve the service life of mechanical equipment.

(5) Lighting effect

⑴ grind and polish various workpiece surfaces to make the workpiece surface more beautiful and generous.

(2) make the workpiece bright and clean without returning light.

For some unique main purpose workpieces, sandblasting can be used to finish different back gloss or matte at will. For example, the surface of stainless steel plate workpiece and wooden furniture is matted, the decorative pattern on the surface of frosted glass, and the texturing production and processing of its fabric surface.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |