Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

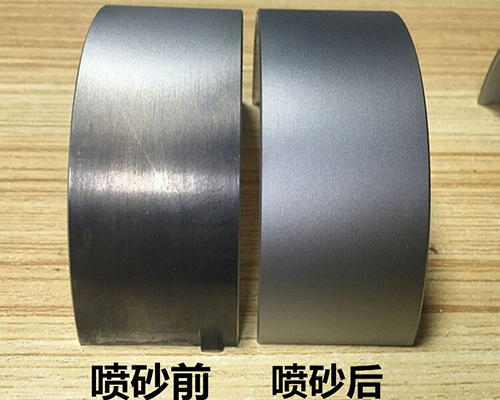

The traditional Dalian sanding and derusting is to use manual derusting, knock with a hammer and brush, and then remove the rust from the surface of gold 1653. In this way, compared with spraying sand, the derusting efficiency is low. The quartz sand derusting used in the development process in recent years is to spray the sand onto the metal surface with air pressure and water pressure, and the sand strikes the metal surface. The effect is the same as hammer and hand brush, so that the rust is removed from the metal surface. Quartz sand is only a kind of abrasive, which needs external force to remove rust, so it can be shot by high-pressure air jet or shot blasting machine.

1. Chemical derusting method: it is mainly a derusting method that uses the chemical reaction between acid and metal oxide to remove the rust products on the metal surface of high-efficiency sand making machine, that is, commonly known as acid pickling derusting, which can only be operated in the workshop;

2. Small pneumatic or electric derusting: it is mainly powered by electricity or compressed air, equipped with appropriate derusting device for reciprocating motion or rotary motion to meet the derusting requirements of various occasions;

3. High pressure water abrasive derusting: use the impact of high-pressure water jet (plus the grinding effect of abrasive) and water pry to remove the rust and coating on the steel plate of sand making machine. It is characterized by no dust pollution, no damage to the steel plate, greatly improving the derusting efficiency, up to more than 15m2 / h, and good derusting quality. However, the steel plate after derusting is easy to rust again, so it must be coated with special wet derusting coating, which has a great impact on the coating of general performance coatings;

4. Apply anti-oxidation paint: apply mineral oil, paint or fired enamel, plastic spraying, etc. on the surface of iron products of sanding machine. The steel surface is coated with a layer of metal that is not easy to rust by electroplating, hot plating and other methods, such as zinc, tin, chromium, nickel and so on. These metal surfaces can form a dense oxide film to prevent iron products from rusting due to contact with water, air and other substances. A dense and stable oxide film can also be formed on the surface of iron products by chemical methods to prevent rust of iron products.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |