Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

As an important surface treatment process, Dalian shot blasting has a wide range of applications in metal processing, automotive manufacturing, shipbuilding, bridge construction and other fields. In the future development, with the advancement of technology and the improvement of environmental awareness, shot blasting technology will continue to improve and innovate, providing more efficient and environmentally friendly surface treatment solutions for industrial production.

The advantage of shot blasting processing is that it can efficiently and quickly treat the surface of workpieces, and is suitable for workpieces of various shapes and materials. It can remove surface oxide layers, oil stains, and impurities, while increasing surface roughness, improving surface hardness, and wear resistance. In addition, shot blasting can improve the surface quality of the workpiece, enhance the adhesion of the coating, and extend the service life of the workpiece.

How to choose suitable Dalian shot blasting equipment and abrasives?

1、Choose shot blasting equipment

Workpiece size and shape:

If the workpiece is large or has a complex shape, it is necessary to choose equipment with a large workspace and flexible shot blasting system to ensure comprehensive coverage of the workpiece surface. For example, for large steel structural components, a through type shot blasting machine can be selected, where the workpiece passes through the shot blasting chamber on the conveyor belt, achieving efficient surface treatment.

For small workpieces, you can choose a drum type shot blasting machine or a hook type shot blasting machine. The drum type shot blasting machine is suitable for batch processing of small parts, while the hook type shot blasting machine is convenient for processing individual or small batches of workpieces.

Production demand:

Consider production efficiency requirements. If high-yield surface treatment is required, equipment with high automation and fast shot blasting speed can be chosen. For example, continuous shot blasting machines can achieve uninterrupted production and are suitable for large-scale production scenarios.

Assess the reliability and maintenance costs of the equipment. Choose equipment with reliable quality and easy maintenance to ensure long-term stable operation. You can view the brand reputation, user reviews, and after-sales service of the device.

Surface treatment requirements:

Determine the parameters of the shot blasting equipment based on the surface treatment requirements of the workpiece. For example, if a specific surface roughness needs to be achieved, appropriate shot blasting speed and abrasive particle size can be selected. Coarse abrasives and higher shot blasting speeds typically result in rougher surfaces.

For workpieces with special surface quality requirements, such as automotive parts, precision mechanical parts, etc., it may be necessary to choose equipment with precise control of shot blasting parameters to ensure consistency and quality of surface treatment.

2、Choose abrasives

Workpiece material:

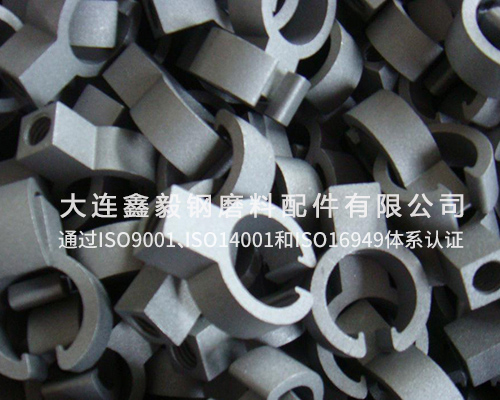

Different types of abrasives need to be selected for different workpiece materials. For example, for surface treatment of steel, commonly used abrasives include steel balls, steel wire cutting balls, etc. Steel balls have high hardness and wear resistance, making them suitable for removing hard oxide scales and rust. Steel wire cutting pellets have good cutting ability and are suitable for removing stubborn attachments.

For softer materials such as aluminum alloys, non-metallic abrasives such as glass beads and ceramic pellets can be chosen. These abrasives will not cause damage to the surface of the workpiece and can achieve good surface treatment effects.

Surface treatment requirements:

If it is necessary to remove thicker oxide scales or rust layers, larger grit abrasives can be chosen. Larger grit abrasives have stronger impact force and can effectively remove stubborn impurities.

For workpieces that require low surface roughness, smaller grit abrasives can be chosen. Abrasives with smaller particle sizes can produce finer surfaces, suitable for workpieces that require coating or electroplating.

Hardness and shape of abrasive:

The hardness of the abrasive should be selected based on the hardness of the workpiece. If the hardness of the abrasive is too high, it may cause excessive wear on the surface of the workpiece; If the hardness of the abrasive is too low, it may not achieve the desired surface treatment effect.

The shape of the abrasive can also affect the surface treatment effect. Spherical abrasives typically produce a more uniform surface roughness, while angular abrasives have stronger cutting ability and are suitable for removing harder impurities.

In actual production, shot blasting is usually divided into two methods: dry shot blasting and wet shot blasting. Dry shot blasting is suitable for cleaning and increasing roughness on the surface of workpieces, while wet shot blasting is suitable for polishing and improving the surface of workpieces. Different types of shot blasting equipment also have different working principles and applicable ranges, such as compressed air shot blasting machines, mechanical shot blasting machines, rotary shot blasting machines, etc.

The main principle of shot blasting is to remove the oxide scale, oil stains, and rust on the surface of the workpiece through the impact and peeling effect of the projectile in a high-speed environment, and form a moderately rough concave convex structure on the surface. This not only improves the surface hardness and wear resistance of the workpiece, but also increases the surface roughness, which is beneficial for coating adhesion and improving surface quality.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |