Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

Dalian shot blasting, as a common surface treatment technology, plays an important role in industrial production. It not only improves the surface quality and coating adhesion of workpieces, prolongs their service life, but also has advantages such as high efficiency, environmental protection, and energy conservation, and is widely used in various industries. In future industrial production, shot blasting processing will continue to play an important role, continuously improving technology, improving processing quality, and promoting industrial development.

The advantage of shot blasting processing is that it can efficiently process large batches of workpieces, improve production efficiency, and effectively remove various surface impurities and oxide layers, improving the surface quality and accuracy of workpieces. Shot blasting can also achieve shot peening strengthening of the workpiece surface, enhance the strength and wear resistance of the workpiece, and extend its service life.

What is the effect of Dalian shot blasting on the surface treatment of steel products?

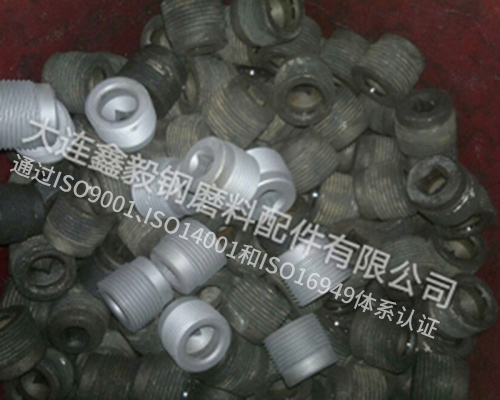

Shot blasting is a commonly used surface treatment method suitable for cleaning and strengthening steel products. During the shot blasting process, metal particles or abrasives are sprayed onto the surface of steel products through a high-speed rotating casting shot blasting machine, thereby removing surface oxides, rust, oil stains, and other impurities, making the surface clean and flat. In addition, shot blasting can also increase the surface hardness and roughness of steel products, improve their wear resistance and corrosion resistance.

The effectiveness of shot blasting mainly depends on the selected shot blasting materials, processing parameters, and equipment quality. In general, selecting a casting shot blasting material with moderate hardness and uniform particles can achieve cleaning and strengthening work without damaging the surface of steel products. Appropriate processing parameters can ensure that the contact and impact forces between shot blasting materials and steel products are moderate, avoiding excessive wear or deformation. High quality shot blasting equipment can ensure processing efficiency and stability of processing quality.

Shot blasting is a common surface treatment technique, also known as shot blasting or shot cleaning. It uses a high-speed rotating shot peening wheel to spray high-speed and high-pressure metal or non-metal particles onto the surface of the workpiece, in order to remove surface defects such as oxide layers, rust, oil stains, and welding slag, thereby achieving surface cleaning and processing beautification. Shot blasting is widely used in industries such as aerospace, shipbuilding, automotive, mechanical manufacturing, and bridge construction.

The principle of shot blasting is to use high-speed particles to impact the surface of the workpiece, remove surface impurities through the action of force, and improve surface roughness and enhance the strength of the workpiece surface. Shot blasting processing can use particles of different materials such as steel shot, cast iron sand, aluminum sand, glass beads, etc. Suitable particles can be selected for processing according to different workpiece materials and requirements.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |