Welcome to the official website of Dalian Xinyi Steel Metal Surface Treatment Co., Ltd!

Dalian Xinyi Steel Metal Surface Treatment Co., Ltd

Contact: Manager Zhang

Telephone: 0411-39630390

0411-39569620

mobile phone:13795133932

website:en.dlxyg.com.cn

Address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Office worker: Quanshui P3, Ganjingzi District, Dalian

Sandblasting is a common metal surface treatment method widely used in fields such as automobiles, ships, and airplanes. It can change the appearance, texture, and roughness of metal surfaces, improve the wear resistance and corrosion resistance of metal products. Sandblasting processing has advantages such as fast, pollution-free, and environmentally friendly, but it also has disadvantages such as noise, dust, and processing limitations. I hope that through continuous technological improvement and innovation, sandblasting processing can be widely applied and developed in the future.

Sandblasting can be used for processing different materials and can handle complex shapes and large-sized workpieces. Sandblasting can remove surface dirt, oxides, and scratches, improving surface quality and smoothness. Sandblasting can achieve surface roughness control by controlling the spray pressure and abrasive particle size, meeting the needs of different applications. Sandblasting processing does not produce harmful gases and wastewater, which meets environmental requirements.

Is Dalian sandblasting suitable for the treatment of small parts?

The material of the workpiece is an important factor. Sandblasting is suitable for many types of materials, such as metals, plastics, ceramics, etc. For some fragile or easily damaged materials, such as glass, ceramics, etc., it may be necessary to choose appropriate grinding materials and sandblasting pressure to avoid additional damage to the workpiece.

Secondly, the shape and size of the workpiece also affect the applicability of sandblasting processing. For small parts, due to their relatively small surface area, small sand particles can be used for sandblasting to maintain surface smoothness and uniformity. In addition, sandblasting usually requires a certain distance and angle to ensure the impact effect of sand particles on the surface of the workpiece. For some small and complex shaped parts, special processing techniques and equipment may be required to ensure the sandblasting effect.

Thirdly, surface characteristics are one of the important factors determining the applicability of sandblasting processing. Sandblasting processing is mainly used to remove surface oxidation layers, oil stains, scratches and other adverse phenomena. For some small parts with high surface roughness requirements, additional polishing or grinding processes may be required to achieve the required surface quality.

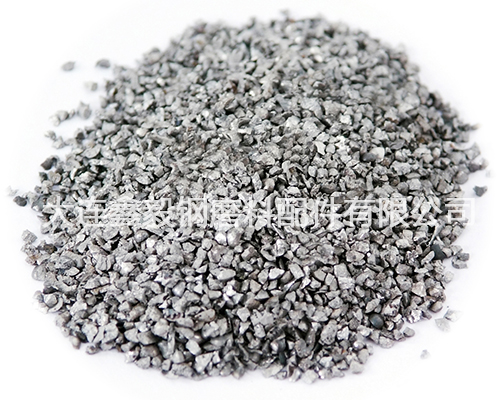

The principle of sandblasting is very simple, which is to use a sandblasting machine to spray hard particles onto the metal surface. The principle of a sandblasting machine is similar to a compressed air spray gun, which mixes compressed air with abrasive and sprays it out, forming a high-speed sandblasting flow that hits the metal surface. A sandblasting machine generally consists of three parts: a compressed air system, a sand supply system, and a sandblasting gun. Among them, sand materials are generally particles with higher hardness such as quartz sand, steel sand, or aluminum sand, which are sucked into the sandblasting gun through negative pressure effect, and then mixed with compressed air before being sprayed out.

Sandblasting has a wide range of applications. It can be used for surface treatment of metal products. After sandblasting, metal products can remove surface oxide layers and stains, improving their surface smoothness and texture. Secondly, sandblasting can also create unique patterns and textures on glass and ceramic products, increasing their artistic value. In addition, sandblasting can also be used for surface treatment of plastic products to improve their adhesion and coating adhesion.

![]()

Office address: P3 Quanshui District, Ganjingzi District, Dalian

Factory address: No. 10, Shengsheng Second Road, Dalian Economic and Technological Development Zone

Copyright © http://en.dlxyg.com.cn/ Dalian Xinyi Steel Metal Surface Treatment Co., Lt Specializing inDalian sandblasting,Dalian shot blasting,Dalian blackened surface treatment,Welcome to inquire!

辽ICP备18004327号 Powered by Clouds platform Technical Support:Joint enterprise Era

| Wechat scan Pay attention to our timely information |