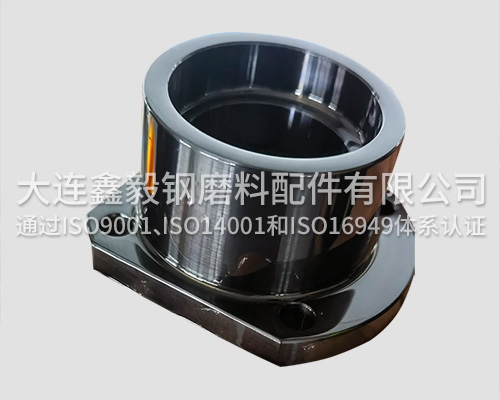

Dalian blackening surface treatment is an important process technology with extensive application value. Through reasonable process flow and technical means, the modification and enhancement of metal surfaces can be achieved, thereby improving the performance and quality of products. In future industrial production, blackened surface treatment will continue to play an important role in providing better assurance and support for the manufacturing of various products.

Blackening surface treatment can effectively improve the corrosion resistance of materials, prolong their service life, and improve their appearance quality. Therefore, it is widely used in industries such as aerospace, automotive manufacturing, and electronic products. For example, in the aerospace field, blackening surface treatment can improve the high-temperature resistance and heat absorption performance of spacecraft, ensuring their safety performance.

Dalian Blackening Surface Treatment: What is it? How to achieve it? Why is it important?

The importance of blackening surface treatment is mainly reflected in the following aspects:

Firstly, blackening surface treatment can improve the heat absorption performance of objects. The black surface has a higher heat absorption rate, which can absorb and conduct heat faster, thereby improving the high-temperature resistance of the material. In some fields with high temperature requirements, such as aerospace, rocket engines, etc., blackening surface treatment can effectively improve the working temperature of materials.

Secondly, blackening surface treatment can improve the surface properties of materials. Black surfaces have better corrosion resistance and wear resistance, which can improve the service life of materials. In fields such as automotive manufacturing and mechanical manufacturing, components that have undergone blackened surface treatment can better resist corrosion and wear.

Once again, blackening surface treatment can improve the surface texture and aesthetics of materials. Black surfaces usually give people a high-end and stable feeling, and products treated with blackening have a more technological and modern feel. In some high-end products or decorations, blackening surface treatment can enhance the added value and aesthetics of the product.

Blackening surface treatment is widely used in fields such as automotive manufacturing, furniture production, and building materials. In automotive manufacturing, blackening surface treatment can improve the surface hardness of automotive components and extend their service life. In furniture production, blackening surface treatment can increase the aesthetics of furniture and increase the added value of the product. In building materials, blackening surface treatment can improve the corrosion resistance of steel and extend the service life of building materials.

Blackening surface treatment usually includes two methods: chemical blackening and thermal blackening. Chemical blackening is the use of chemical methods to form an oxide or sulfide layer on the surface of a material, thereby changing the color and properties of the material. Thermal blackening refers to heating a material to a certain temperature, causing an oxidation reaction on its surface, thereby forming a layer of black oxide film.